Project Overview

I designed and produced the official CAD tutorial materials for the Design for Manufacture module on the Product Design BSc. I had full responsibility for creating a departmental resource that teaches second year students how to design injection mouldable parts with confidence.

Deliverables

3D Printed Prototype

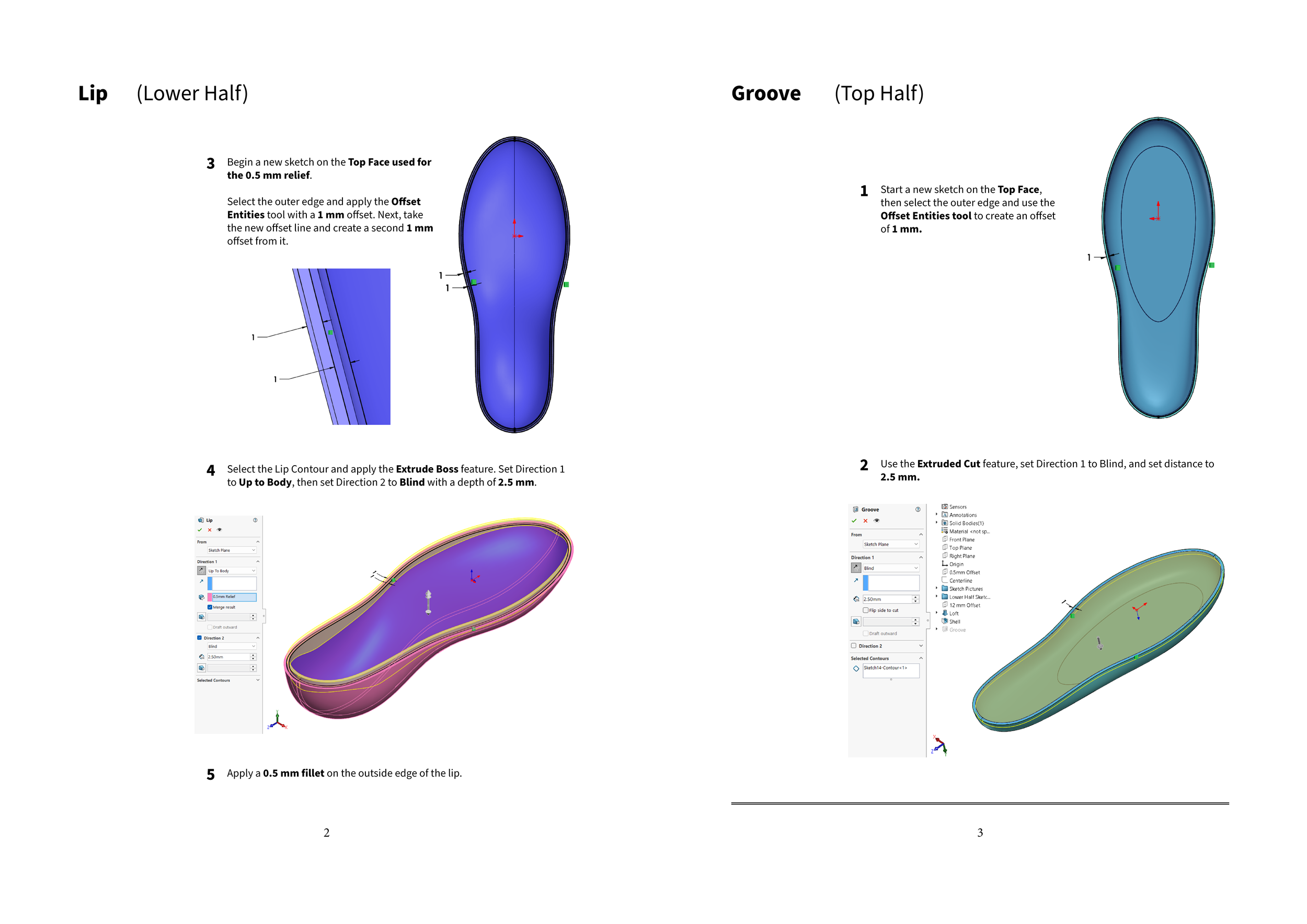

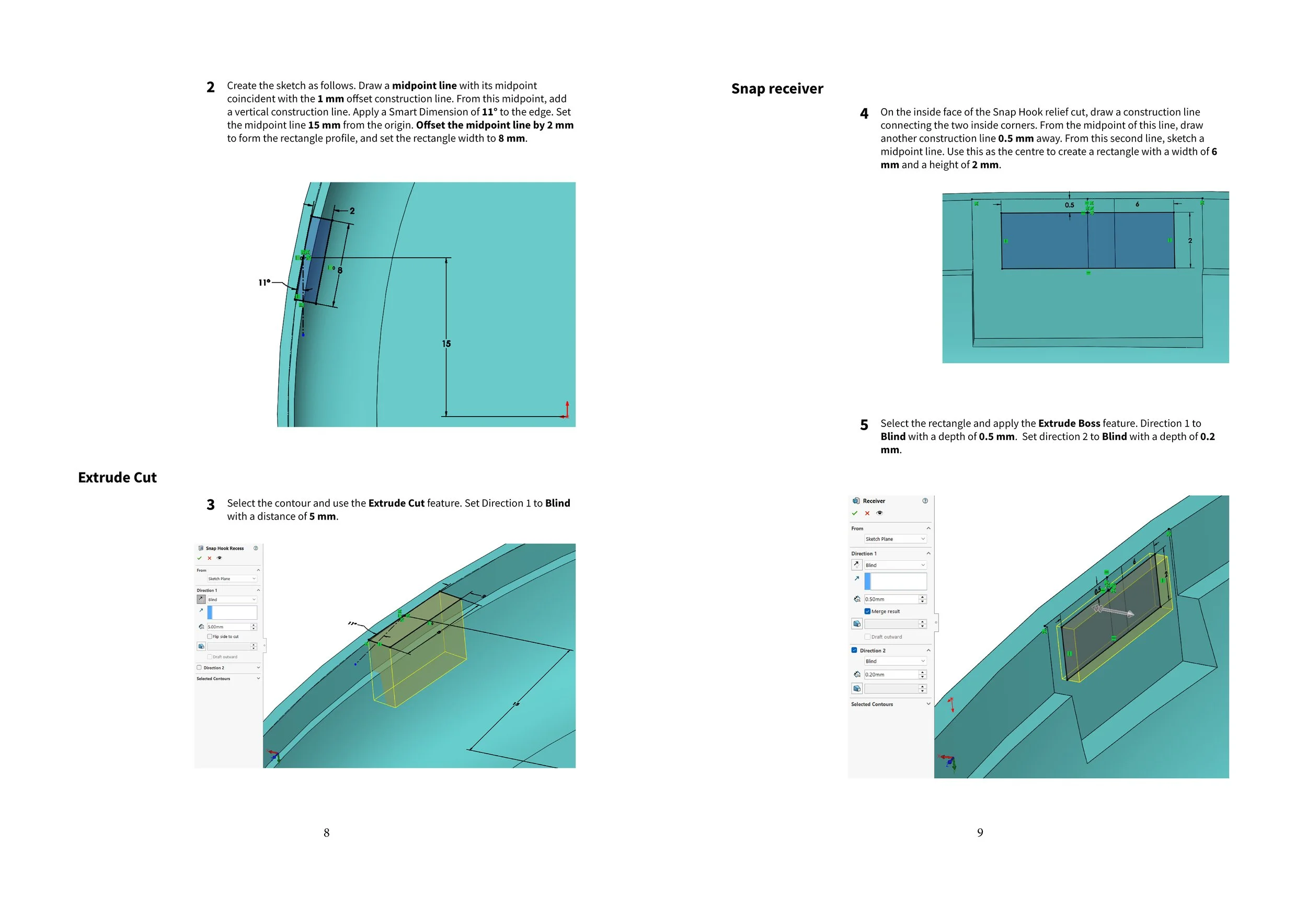

The tutorial embeds core DfM principles throughout, including sensible draft angles, consistent wall thickness, clear parting strategy, robust assembly bosses, accurate PCB mounting features, reliable snap hooks, and precise lip and groove joints. The reference model demonstrates each decision in context so learners can see why as well as how.

Impact

The School of Mechanical Engineering adopted my tutorial as part of the DfM curriculum. It helps students progress faster from sketch to manufacturable parts, reduces rework in the workshop, and improves the consistency of final builds.

Reflection

The challenge was balancing realism with teachability. I iterated the order of operations and simplified where needed, keeping only the details that matter in industry while maintaining a clear, confidence building sequence.